Using robots in assembly lines and manufacturing is nothing new. The first industrial robot was designed in 1954 and was capable of moving objects from one point to another.

It wasn’t until 1980 that the rate of new robotic started to climb exponentially. The number of factory robots around the world has hit 2.7 million. They are used in everything from automotive to electronics, from medical to industrial.

Robots are highly desired in many cases when the tasks are too dirty, dangerous, or dull for a human.

Look at that assembly line of robots.

You’ll also notice that there is not a person in sight. Robots have historically been isolated from human contact as a safety measure, but that is changing quickly.

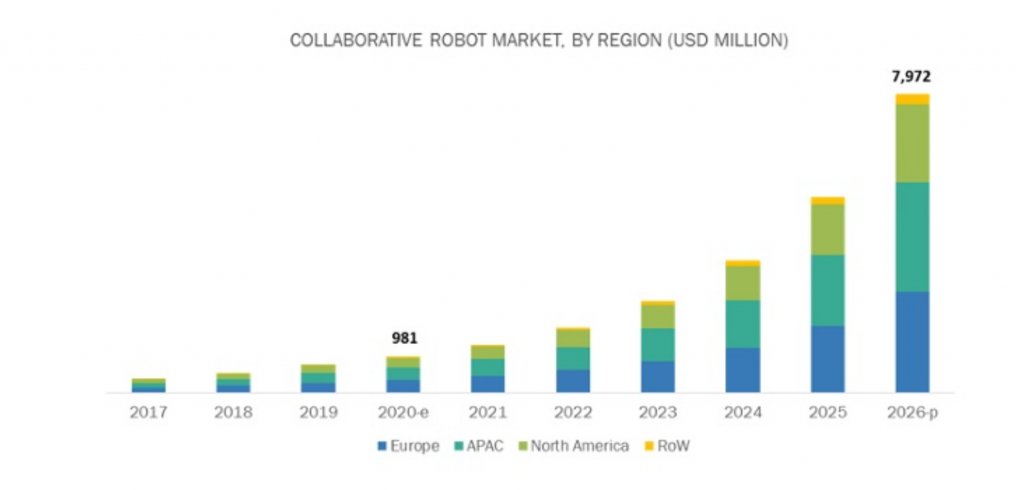

Gone are the days when robots were mounted to the floor or confined to a protective cage. Collaborative robots (cobots) are now the fastest-growing segment in industrial automation.

Thanks to design features such as sensors and lightweight materials, robots are now able to interact directly and safely with humans. We can now literally release the robots.

These cobots can measure, analyze, and respond to the world around them. The latest generation of cobots don’t even use programming, but instead, learn their task from their human teacher.

The human can manually move the robot through the steps of a job and it actually learns what it should be doing.

Modern cobots can move around a manufacturing floor or warehouse without specialized floor markings or racking systems. Meaning that the implementation costs of automation are a lot less than it previously was. This will allow more mid-size companies to start utilizing automation.

It’s important to note that this trend is all about collaboration between robots and humans. When the two can work together, it’s less about robots taking over jobs and more about robots enhancing the workplace and improving efficiency.

Amazon alone has more than 200,000 mobile robots working inside its warehouse network. These robots have helped the company fulfill its ever-increasing promises of speedy deliveries.

At one point the company said it’s one-day shipping options would not even be an option without the help of its fleet of robots.

The cobot market is expected to grow to a value of almost $12 billion by 2030.

Right now, the biggest cobot center in the world is being built in Denmark. The Danish companies Universal Robots and Mobile Industrial Robots are investing almost 33 million Euro in the construction.

These two companies are separate entities, but both owned by Teradyne (NASDAQ: TER) which I mentioned last Tuesday.

The two companies previously opened a cobot hub in Barcelona last year to promote collaborative automation in Southern Europe.

Although not the core of its business, Teradyne is going to continue to invest aggressively in the development of new robotics technology. Since 2015 it has acquired four different robotics companies for its portfolio, including the two mentioned above.

Management hopes its automation unit will be posting revenues exceeding $1 billion in 2021.

The expansion of 5G technology will help accelerate this trend as instantaneous data transfer becomes the norm. Collaborative robots are going to be one of the biggest trends in manufacturing over the next few years.

I’ll of course be following it to find the best ways to profit.

To your prosperity and health,

Joshua M. Belanger

Executive Publisher & Founder