For the first time in decades, the automobile industry is completely fractured.

Instead of the “Big 3” in the U.S., there are now a dozen companies competing for customers’ loyalty.

Tesla Inc. (NASDAQ: TSLA) alone has grown from a fascinating idea into a $384 billion giant. NIO Limited (NYSE: NIO) over in China is doing the same, already worth $66 billion.

That means each company, including Ford Motor Co. (NYSE: F) and General Motors Co. (NYSE: GM) have to just get better at what they do: bring down costs, offer new and customized models and change how they manufacture their products.

And that’s what these car companies are doing.

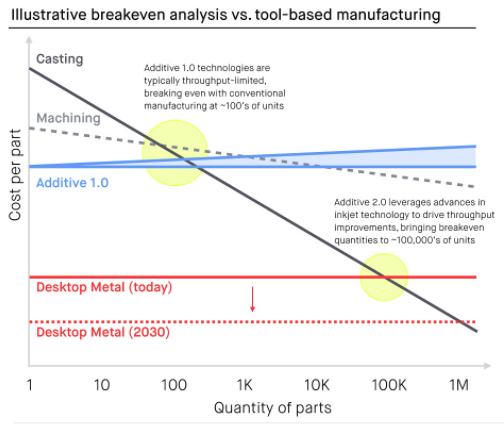

One of the largest costs for car manufacturers is tooling and casting out their thousands of parts. And unless you are going to make hundreds of thousands or even millions of those parts, you don’t really see any savings long term.

For some models, like the Ford F-series, that is an expense that makes sense. The company churns out nearly a million of those trucks each year.

But for dozens of other models, the individual parts can get expensive. That’s why they are turning to what many think is a dead idea: 3D printing.

As I noted back in August, this isn’t a dead industry. The kinds of printers that take hours to create little plastic knickknacks are still just as useless. But printers can work with many more materials and operate within a large manufacturing process easily.

And one company has figured out how to produce not only the fastest of these new second generation printers. It has done so with investments from the likes of Ford and BMW.

Car companies have been using additive manufacturing, or 3D printing, for years. But before now, it only made sense to do so for prototypes and small production runs.

After a certain number of cars go through the manufacturing process, paying for large-scale molds and the tools to create them out of solid metal ends up being cheaper.

But one company soon to hit the market is branding what it does as “Additive 2.0.”

Desktop Metal has three models already shipping with another “super system” launching next year. Its printers can make everything from fiber-reinforced parts for the aerospace industry to larger, dense parts for the automotive industry.

The point, however, is that this is a metal company, as its name suggests. Those expensive molds and tools car makers have used for years create a lot of scrap and left-over material. They are also extremely energy intensive.

Grab a piece of paper and pen to write this down…

Because you’re about to see the name and ticker symbol of the ONLY 5G STOCK every investor should own.

You can get the name and ticker of this company right here, no strings attached. But you better act fast…

Because the Federal Communications Commission, the government agency in charge of 5G, just scheduled a major announcement that would send shares soaring once announced.

Don't miss out. Click Here to Get #1 5G play for 2020 before the next market close.

Desktop Metal’s printers create virtually no waste and use far less energy. This is exactly what the auto industry needs to use to cut their costs, both on parts for smaller runs of models and on their electric bills.

Of course, as noted, for larger runs of models like the F-series, this doesn’t make sense, right?

Well, not so fast.

Desktop Metal has vastly improved the cost structure of manufacturing.

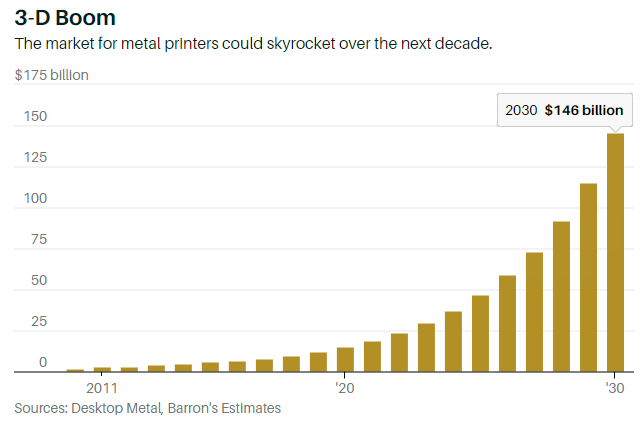

Additive manufacturing used to only be cheaper for the first 100 or so parts produced. Desktop Metal’s printers are now cheaper through the first 100,000 parts. And the company expects to increase that closer to 1 million in the next decade.

That means that eventually, even the largest production runs will integrate this technology as a simple cost saver.

Already many models use this kind of technology. I pointed out in August that 75% of the parts in the 2020 Chevy Corvette were 3D printed. With all of these new companies competing in this fractured environment, this new technology is going to be highly valued.

Desktop’s model is another huge benefit for the company.

It not only holds all the patents on this additive 2.0 technology and produces the printers. Its customers have to come back and pay for the materials and consumables that go into the process each year.

A single “Production System” model, its big printer due out next year, is going to cost customers $2.2 million to buy. But they’ll also have to pay $450,000 each year for the materials and service of each machine.

Again, this is still cheaper than the old way of manufacturing. So, they’ll gladly pay this recurring cost over years of service.

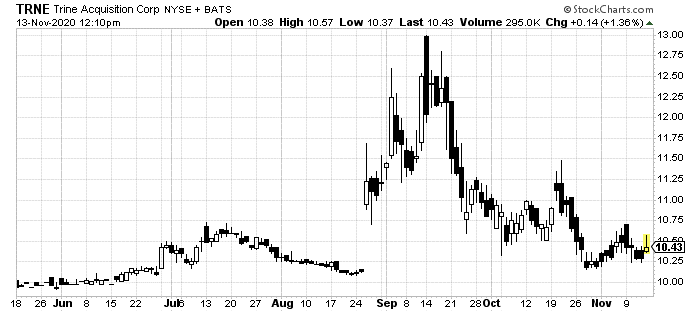

Desktop Metal is going public soon through a reverse merger with a SPAC called Trine Acquisition Corp. (NYSE: TRNE).

This deal is expected to bring in about $526 million to the company’s coffers, giving it a total price tag of $2.5 billion.

Shares of TRNE popped up to nearly $13 when the deal was first announced in late August. But have since come back down, opening a great opportunity on this quickly emerging play.